The Sumobot competition

The SumoBot is an annual competition of robot fights organized by the ESIEE engineering school in Paris.

The purpose of this competition is to make two robots compete in a circular ring until there is only one left.

It is possible to participate alone or in a team.

The prerequisites for the competition

The sumobot is a competition where:

- Two robots confront each other in a 0.7m ring

- It is necessary to take the opponent robot out of the ring to win a round

- A game takes place in several rounds, called "rounds"

- The one who wins the most rounds wins. In general, a game lasts 2 to 3 rounds

- Several prizes are distributed according to the ranking of each competitor

- The greatest constraint of this competition: the robots respect maximum dimensions of "10 x 10" and weigh at most 500 g

The design

The sumobot is a competition where:

- Two robots confront each other in a 0.7m ring

- It is necessary to take the opponent robot out of the ring to win a round

- A game takes place in several rounds, called "rounds"

- The one who wins the most rounds wins. In general, a game lasts 2 to 3 rounds

- Several prizes are distributed according to the ranking of each competitor

- The greatest constraint of this competition: the robots respect maximum dimensions of "10 x 10" and weigh at most 500 g

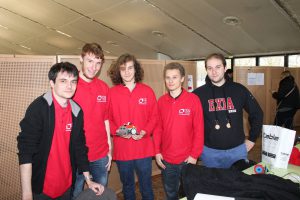

The team

To carry out the project, we formed a team of five people, including:

- Two 5th years (in black)

- Three 1st years (in red)

The team logo

In parallel with the design of the project, we created a logo for the competition, which is as follows:

The general organization of the project

Being in engineering school, we decided to create a robot entirely to add a little challenge.

First of all, it was necessary to divide the tasks into several categories:

- a team for robot design and material selection

- a team responsible for designing and programming the robot's behaviour

- one to two people who manage the project as a whole, as well as the ordering and receipt of materials

Robot design

The project started with an analysis of the prerequisites for the competition: the robot should not exceed the dimensions of 100x100 (in mm).

Based on the size of the robot, we brainstormed to determine its functions, shape, materials and electronic components.

Then, we made the 3D model of the robot in SolidWorks to be able to not only visualize the structure but also to print it.

Thanks to the selected components, we carried out the electronic paper assembly of the robot.

Situation modeling and programming

First we watched some videos on the net about the SumoBot competitions of the past years to analyze the behavior of the different robots.

We then thought about a strategy to get the other robots out of the ring with ours. Several situations were carried out on paper.

Then, we modelled these situations in the form of logigrams. As a reminder, a flowchart is a diagram that represents a sequence of logical events that execute one after the other in accordance with the conditions given by the designer.

Project management

This project was carried out in 2016. At that time, I was in the first year of the Cesi Exia engineering school in Rouen.

So it was the president of the robotics club who took care of the project management.

After careful consideration, we drew up a list of the equipment to be ordered and he was responsible for ordering the equipment from the school.

Realization of the robot

Assembly: structure and electronics

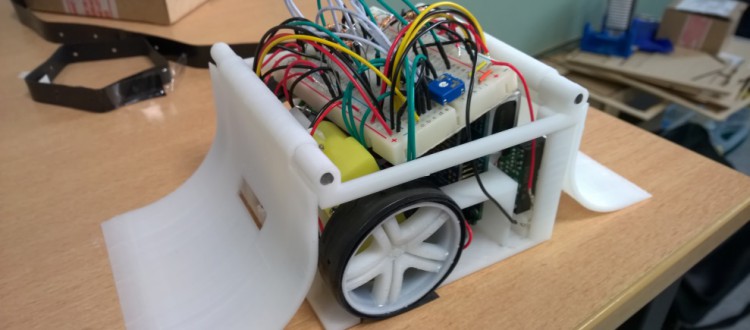

We have chosen to build a square robot of 100x100 (in mm) to optimize the available space.

The weight constraint was respected: the robot weighed 498 grams out of the authorized 500 grams.

The components were assembled by welding in groups of three people for several hours at the school's research laboratory. This is what the robot looks like when it is almost finished:

The components used for assembly

Here are the different components that were used to build and operate the robot:

- A frame printed in 3D using a 3D printer from the research laboratory.

- Arduino programmable card

- Two motors each with a reduction of 1 / 45 to have a lot of torque

- A motor shield connected directly to the Arduino pins to facilitate motor management

- Two infrared sensors on the front of the robot to capture opposing robots

- Four line sensors (in each corner of the robot, to pick up the lines at the edge of the ring and prevent the robot from leaving the ring)

The code in C++ with Arduino

It is possible to program on an Arduino in C / C++ using an IDE of the same name as the card.

I was on the situation design and programming team. We followed the flowchart created during the design phase to implement and optimize our algorithm.

We saved time on this step because from the Arduino IDE, it is possible to upload your code from your computer directly to the Arduino card by connecting the PC and the Arduino by a simple USB cable.

The day of the event

On the day of the SumoBot competition, our team went to the ESIEE in Paris to participate in the event with the robot made. Many participants and robots were present:

Notes

If you would like to have even more details about our participation in the event and the result of the competition, I invite you to consult this link:

If you are also interested in the annual SumoBot event, you can follow the news feed on the official website: